ABS filament

(Acrylonitrile Butadiene Styrene)

Basic Info

ABS filament is a technical material suitable for printing mechanically stressed parts, thanks to its high tenacity and temperature resistance. Its surface can be smoothed with acetone. The main disadvantage is significant warping and toxic fumes.

Description

ABS plastic is made out of oil-based resources and it has a much higher melting point than PLA plastic. It’s also stronger and harder. Because of these particular features, ABS is widely used for purposes ranging from car bumpers and motorcycle helmets to musical instruments, golfclubs and Lego. ABS printing requires specific conditions for successful results. It’s important to run the prints in a well-ventilated room because the material releases fumes and substances that could pose a potential health risk. However, when ventilating the room, do not create a draft around the print – this will negatively impact the result.

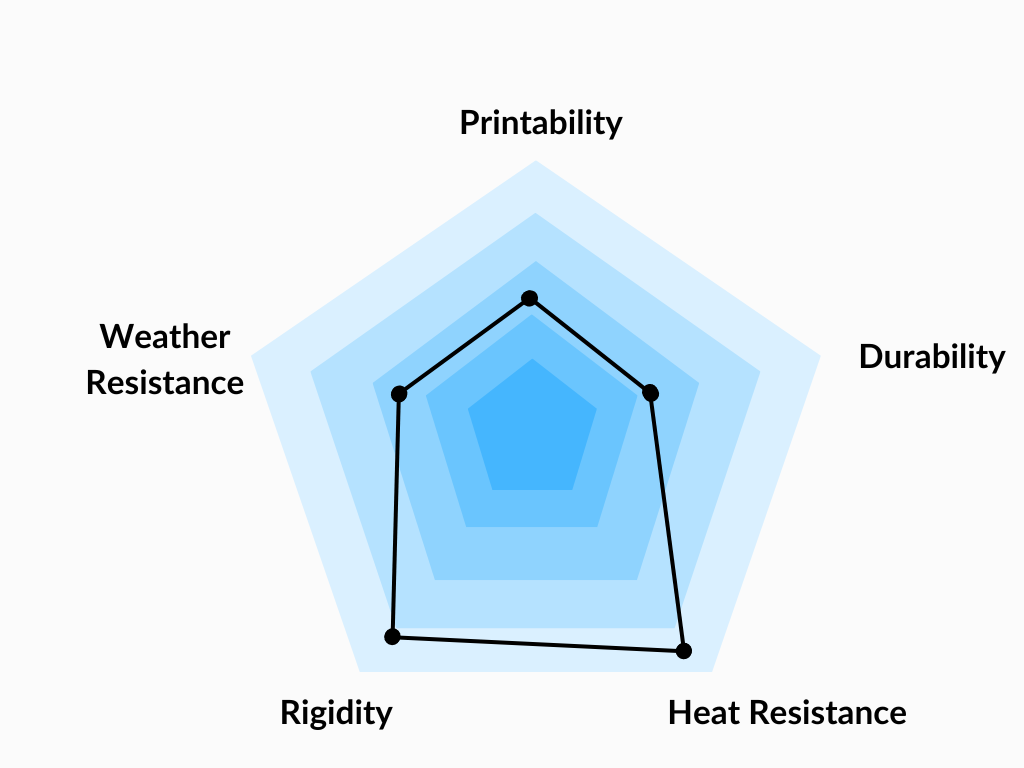

Chart

Pros and Cons of using ABS

| Pros | Cons |

|---|---|

| Very sturdy and hard | Made out of oil, so more damaging to the environment |

| Suitable for machine or car parts | Deformes when not being print on a heated surface |

| Higher melting point | More difficult to print |

| Longer lifespan | Therefore, you need ventilation |

Applications

Automotive Industry

The ABS filament is widely used in the automotive industry because it is lighter yet stronger as compared to other plastics. The use of ABS filament reduces the overall weight of the vehicle by 10 percent, thus making the vehicle fuel-efficient. Most manufacturers use ABS filament to make wheel covers and dashboards.

Pipes and Fittings

The pipes and fittings manufacturing industries extensively use ABS as the popular filament for 3D printing. The reasons for its popularity are that it is light-weight, has a very low-temperature melting point, and is highly reliable. The filament can also withstand wear and tear and is easy to install and maintain. This makes it a great choice for creating prototypes of pipes and fittings.

Toy Industry

The toy industry also prefers the ABS filament as it is highly durable and can withstand high temperatures. Also, the ABS filament is less brittle as compared to its counterparts and hence forms a great material to make toys that are safe for children.

Sports Equipment

For sports equipment, manufacturers prefer using the ABS as filament for 3D printers because of its durability and ability to withstand pressure. ABS filament is used to manufacture products such as running shoes, bike helmets, golf masks, mouth guards, etc.