Daemon3D’s Makerspace Initiative for STEM and Arts Teachers

UK-Based Daemon3D Print Launches Makerspace Services to Support STEM and Arts Teachers

Daemon3D Print, a UK-based company, has launched a new initiative to provide STEM and arts teachers with the tools and support they need to deliver engaging lessons on 3D printing and scanning technologies. The program is targeted at key stages 3 and 4 educators and is part of Daemon3D’s Makerspace services.

The Makerspace services offer curriculum support for using 3D printers, laser cutters, 3D scanners, robotics, and other related technologies. The company provides lesson plans and course materials designed to pique students’ interest and deepen their understanding of these technologies. The goal of Makerspace is to help teachers create dynamic learning experiences that enable students of all abilities to find their strengths and reach their potential.

Daemon3D’s Makerspace services aim to provide the necessary technical support and educational tools for teachers to effectively integrate these technologies into their lessons. Nicola Stokes, the late Director at Daemon3D, expressed concern that many schools were left unsupported with makerspace technologies, leading to expensive equipment being underutilized. With the Makerspace services, teachers can receive the support they need to deliver engaging and effective lessons that make use of these technologies.

Source:

https://3dprinting.com/news/initiative-for-stem-and-arts-teachers-launches/

Ontario Students Print Human-sized Robot

February 16, 2023

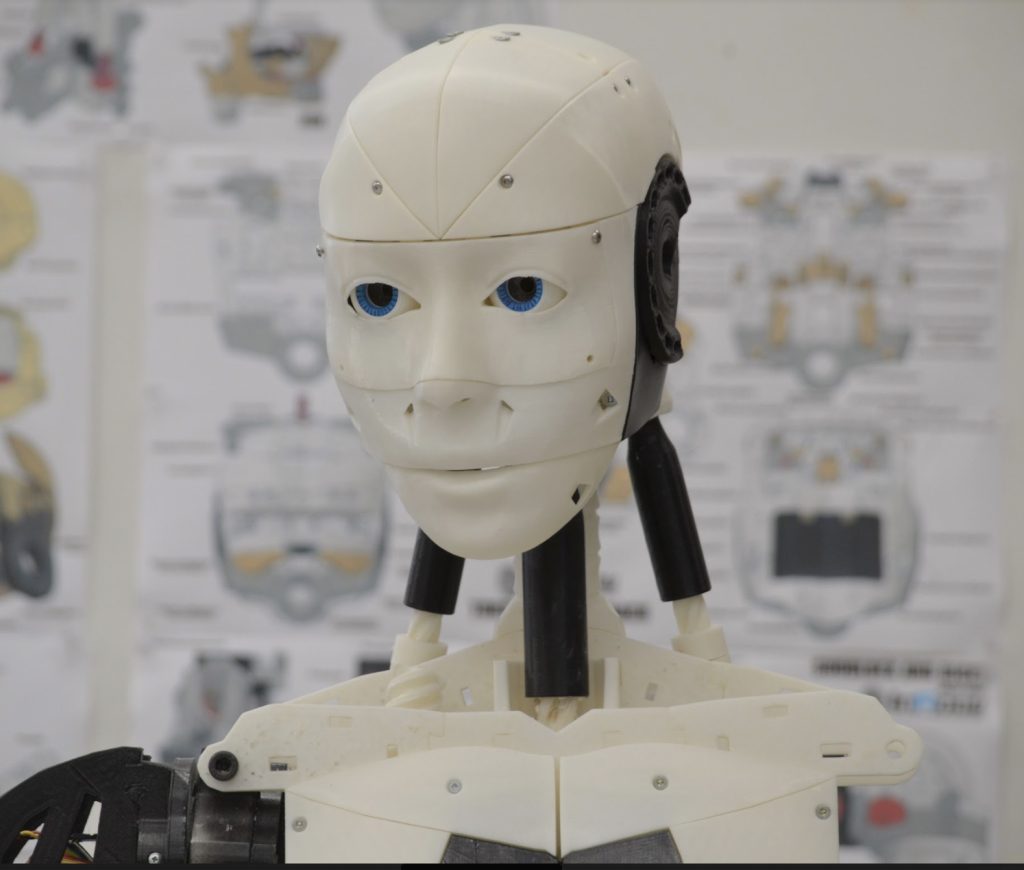

Students at Lasalle Secondary School in Sudbury, Ontario, have been busy building a human-size robot named ‘Lance’ using 3D printing technology.

The robot can respond to verbal commands, answer questions and interact with people. The project was started over two years ago when students were learning online due to the pandemic, and it was initiated by the school’s robotics teacher, Roger Branconnier, to engage students during remote learning.

Branconnier initially started with building a little finger using 3D printing and showed it to the students online. Over time, the finger became a hand, and then the hand became a shoulder. It took hundreds of hours of 3D printing to make over 400 printed parts for the robot. The project continued once classes switched back to in-person learning, and students are currently working on building the left arm of the robot.

The robotics teacher sees the opportunity to add more features to the project, such as adding cameras in the eyes for facial recognition and building gloves that mimic the robot’s actions. The project has been a unique and exciting experience for students, with one Grade 12 student, Matthew King, hoping to pursue a career in mechanical engineering.

“I don’t think many students get an opportunity to work on something like this, so the fact that I’ve been lucky to be here at Lasalle and work on something as cool as that or even our smaller robots in the club, it’s been a really cool experience,” said King.

In addition to building the human-size robot, students in the Robotics Club are gearing up for a provincial competition in May. The Skills Ontario Competition will put student programming and engineering skills to the test by building three robots. The competition was canceled last year due to the pandemic, and students are looking forward to participating this year.

Source:

https://3dprinting.com/news/ontario-students-print-human-sized-robot/

World-first Surgery to Help Man Regenerate Jaw Thanks to 3D Printing

March 13, 2023

A surgeon has performed a world-first surgical technique using a groundbreaking biodegradable 3D implant to help a man regenerate half of his jaw lost to cancer.

The part was designed by Australian-Singaporean company Osteopore, and was implanted into the patient, Australian John Manwaring, by surgeon Michael Wagels.

Regeneration

The patient had originally had his jaw reconstructed using a part of a bone in his leg, but the bone disintegrated following further cancer treatment. The new technique involved printing the implant, and wrapping it in a shaving of the lining of the bone. The bone then regenerates inside the scaffolding of the implant.

Over the next two years, the implant will slowly be absorbed into the body, leaving a nice new jawbone for the patient. Not having to perform a second surgery to harvest bone to be used as an implant reduces the overall risk to the patient. If everything happens as it should and the implant dissolves, the risk to the patient is reduced again.

“Because of the way we 3D printed the implant, it has the propensity to enable tissue and vessels to grow into it, not just around it, but through the entire volume of the scaffold,” said Dr Jing Lim of Osteopore.

“That is really down to the porous structure that we incorporated during the printing process, and the understanding of what sorts of materials would be best suited to facilitate this regeneration.”

Hope for the Patient

The breakthrough is directing and supporting the growth of regenerated bone into the scaffolds of the implant, so it’s not just bone cells but also blood vessels that regenerate to keep the cells alive.

“It surprised me that this can be done so close to home, not America, and it’s fantastic that this is available,” said Mainwaring.

“It feels good to know that this technology can help someone else.”

Indeed. And if all goes well, the patient should be able to eat, speak and breathe more easily, as well as gain more confidence about his appearance, which ostensibly had suffered in light of his original condition.

Source:

https://3dprinting.com/news/world-first-surgery-to-help-man-regenerate-jaw-thanks-to-3d-printing/

Costain and Versarien Complete 3D Printed Headwall for Highway Use

March 6, 2023

Versarien PLC, a UK-based advanced materials engineering group, has completed the construction phase of a 3D printed concrete headwall for use in highway projects.

The project was completed alongside a subsidiary of Costain Group PLC, a construction and engineering company who we have covered before when they fabricated the UK’s first printed water chamber.

In the past, headwall structures have been made with precast concrete, which can have limitations on the structure’s shape, and require steel reinforcement.

By using an alkali-activated cementitious material and a 3D printer, Versarien and Costain have been able to create a curved headwall that does not require steel reinforcement.

The headwall has been created as part of the Digital Roads of the Future partnership, a collaboration led by the University of Cambridge, Costain, and National Highways, of which Versarien is a partner.

“We are delighted to have partnered with Costain to produce this innovative structure that we believe provides significant benefits over those produced using traditional manufacturing techniques,” said Neill Ricketts, Chief Executive Officer of Versarien.

“In utilizing Versarien’s materials engineering expertise and understanding of the latest techniques, we have highlighted how new technologies can be employed to provide a solution to improve product performance, lower cost and reduce the carbon footprint. We believe this represents the first use of 3D construction on a National Highways project and we look forward to the headwall being installed, demonstrating the viability and attractiveness of using this technology and Versarien’s know-how on future projects.”

The constructed headwall is due for delivery and installation on one of Costain’s projects for National Highways very shortly.

Source:

https://3dprinting.com/news/costain-and-versarien-complete-3d-printed-headwall-for-highway-use/

-

Polymaker PolyLite ASA Filament 1.75mm 1KGSale Product on sale

₹2,799₹2,699

Researchers Release New Magnetic 3D Printable DNA Model

February 28, 2023

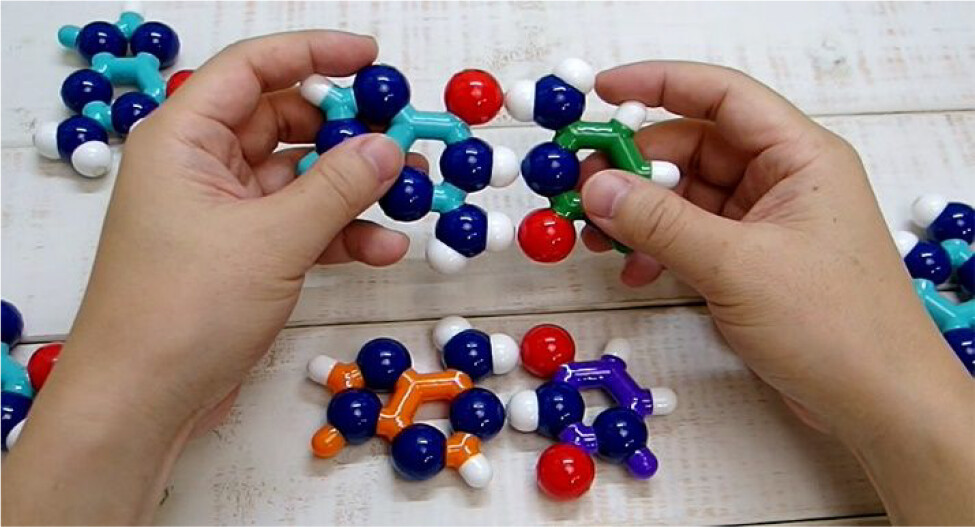

Researchers from Sophia University in Japan have developed a new molecular model to teach students about nucleobase pairing. The BasePairPuzzle uses embedded magnets to accurately mimic hydrogen bonds in molecules, enabling students to visualize and understand the three-dimensional structure of DNA, including the structure of the double helix, and the effects of point mutations.

Most molecular models available in the market cannot represent intermolecular interactions, particularly hydrogen bonds, which are a critical type of attractive force involved in base pairing. The BasePairPuzzle is an innovative design that allows students to feel and see how nucleobases pair with each other. The model can be used to demonstrate that there is great diversity in nucleobase pairs beyond the complementary A-T and C-G pairs and how DNA mutations occur.

The 3D printed puzzle pieces have strategically placed crannies that can fit commercial, cylindrical neodymium magnets, which accurately mimic the hydrogen bonds and electrostatic forces that naturally exist between nucleobase pairs. They’re also buoyant and waterproof, so you can throw them into water and see how they would behave in a more natural setting (i.e floating around in a fluid).

The researchers have made the necessary files for 3D printing BasePairPuzzle pieces available to everyone free of charge, hoping to provide a hands-on experience of nucleobase pairing to as many students as possible.

Source:

https://3dprinting.com/news/researchers-release-new-magnetic-3d-printable-dna-model/

World’s Tallest Carbon-capturing Artificial Tree 3D Printed in Korea

February 20, 2023

Tree.ONE, an exhibit by ecoLogicStudio at the Habitat One exhibition in Hyundai Motor Studio in Busan, South Korea, is a celebration of the convergence of nature and technology.

It is a ‘living’ tree that is designed by artificial intelligence and bio-digitally grown. The exhibit features a 10-meter-tall 3D-printed trunk that supports the inoculation of living photosynthetic microalgae cultures.

The algae-based biopolymers in the structure store captured carbon, making it the world’s tallest 3D printed, self-supporting, carbon-capturing, and storing structure. It has the same photosynthetic and carbon-capturing potential as a mature tree, metabolizing and storing the carbon molecules into its 3D printed bio-plastic structure while releasing oxygen in the atmosphere.

According to the press materials, the exhibit showcases the dawn of a new technological era where contemporary digital and robotic infrastructure is repurposed to fabricate or grow soft, wet, living, bio-digital architectures.

It presents a carbon-neutral civilization where bits, atoms, and cells fuse into one biotechnological landscape. From small photosynthetic systems that enable self-sufficiency to high-density metropolitan clusters that support urban re-metabolization, the exhibit envisions capsules for mobility enabling the emergence of fluid and dynamic urban networks.

To learn more about this project, visit ecoLogicStudio’s Tree.ONE project page.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.

Source:

https://3dprinting.com/news/worlds-tallest-carbon-capturing-artificial-tree-3d-printed-in-korea/