3D printing technology is revolutionizing the way objects are manufactured. One crucial component of this technology is the filament, which acts as the raw material for 3D printing. With a wide range of filaments available, it can be difficult to choose the right one for your project. In this article, we will explore the different types of 3D printing filaments and their unique properties and capabilities.

- PLA (Polylactic Acid) Filament: A Popular Choice for 3D Printing

PLA filament is a biodegradable and eco-friendly material that is derived from natural resources such as corn starch or sugarcane. It is a popular choice for 3D printing due to its ease of use, low shrinkage, and low odor during printing. PLA is also known for its smooth and glossy finish, making it perfect for creating intricate objects like toys, figurines, and more.

- ABS (Acrylonitrile Butadiene Styrene) Filament: Tough and Durable

ABS filament is a thermoplastic material that is well-known for its toughness and strength. It is commonly used for objects that require durability, such as automotive parts, toys, and more. ABS is moisture-resistant, making it an ideal choice for objects that will be used in damp or humid environments. However, it emits an unpleasant odor during printing, so it’s recommended to print in a well-ventilated area.

- PET (Polyethylene Terephthalate) Filament: Food-Safe and Versatile

PET filament is a food-safe material that is often used for objects that come into direct contact with food and beverages. It has excellent layer bonding and low shrinkage, making it ideal for objects that require tight tolerance and dimensional stability. PET is one of the most versatile filaments, as it can be used for a wide range of applications, such as water bottles, food containers, and medical devices.

- Nylon Filament: Strong and Flexible

Nylon filament is a strong, flexible, and durable material that is commonly used for objects that require high strength and resistance to wear and tear. Nylon is also known for its excellent layer bonding and ability to withstand high temperatures, making it ideal for objects that will be subjected to high stress and heat. Some of the applications for Nylon filament include gears, mechanical parts, and objects that require high strength and flexibility.

- TPU (Thermoplastic Polyurethane) Filament: Flexible and Elastic

TPU filament is a flexible and elastic material that is ideal for objects that require flexibility and impact resistance. TPU is commonly used for creating phone cases, toys, and other objects that require flexibility and durability. However, it can be challenging to print with TPU, as it can tend to adhere to the build plate and create stringing.

In conclusion, 3D printing filaments are a crucial component of the 3D printing process, and there are several types available, each with unique properties and capabilities. Whether you need to create objects that require strength, flexibility, or durability, there is a filament that will meet your needs. By understanding the different types of filaments available, you can choose the right one for your project and create high-quality, functional objects with ease.

Featured products

-

Polymaker PolyTerra Marble PLA Filament 1.75mm 1KGProduct on sale₹1,799

-

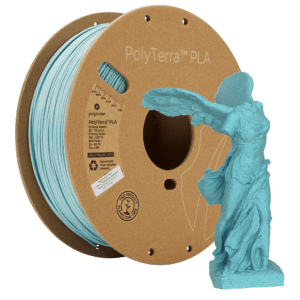

Polymaker PolyTerra PLA Filament 1.75mm 1KGProduct on sale₹1,799

-

Polymaker Polyterra PLA+ 1.75mm 1KGProduct on sale₹1,899 – ₹1,999