PC filament

(Polycarbonate)

Basic Info

Description

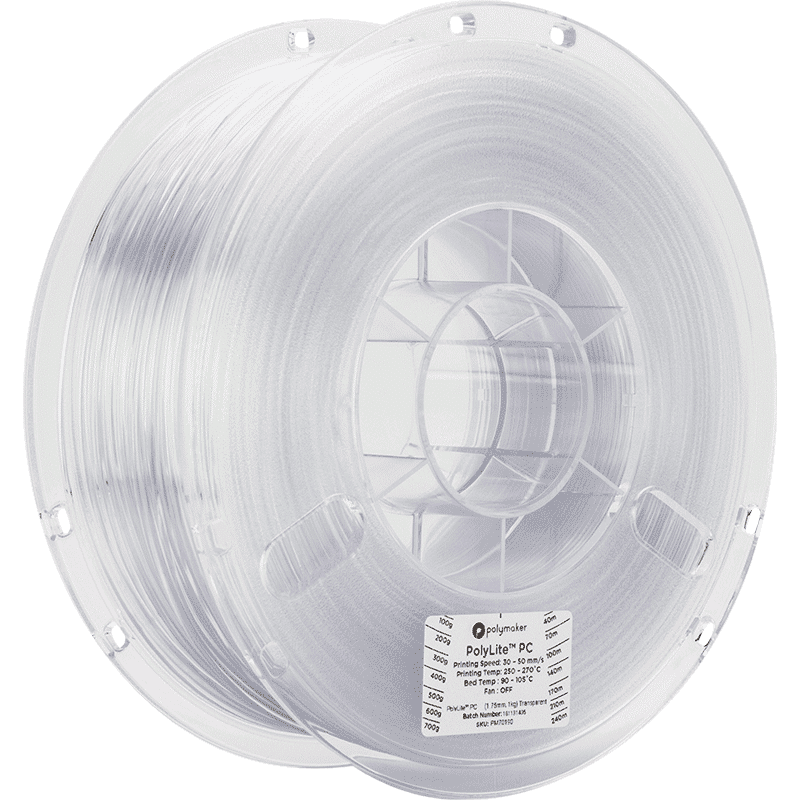

PC Filament (Polycarbonate) is a high-performance, synthetic filament used for fused filament fabrication 3D printing. It is a recyclable material that can be engineered to meet specific application or processing requirements, such as low warping. It’s toughness and rigidity make it an ideal material for higher demanding 3D-printing applications.

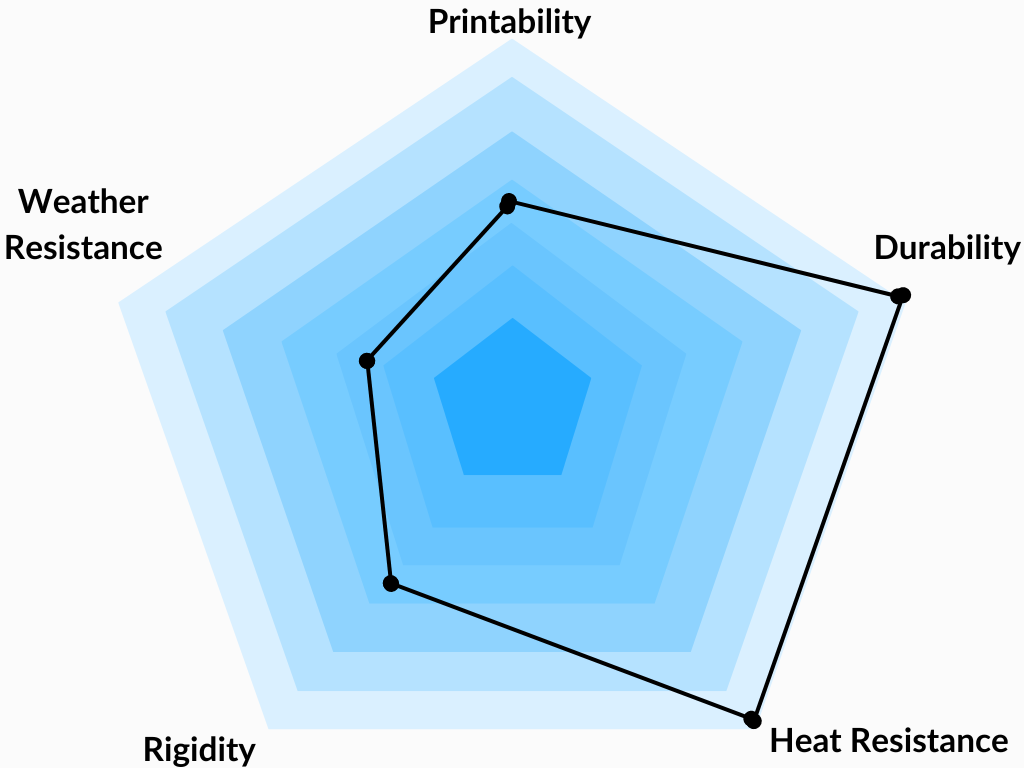

Chart

Pros and Cons of using PC Filament

| Pros | Cons |

|---|---|

| High-temperature resistance | Pure polycarbonate is highly hygroscopic |

| High impact tenacity and tensile strength | High nozzle and bed temperature |

| Pure polycarbonate is transparent | High warping, especially with large models |

| Good electric insulation properties | Application of a separation layer is recommended |

Applications

Medical – Medical equipment parts

Automotive – Headlamp lenses, inner lenses, clusters, door handles, finishing panels, radiator grilles, hubcaps, spoilers

Electric and Electronic Parts – Switching relays, connectors, sensor parts, deflecting yokes, disc carriers, LCD parts, backlit panel parts

Machinery – Electric tools, vending machine parts, fibre bobbins

Safety – Safety goggles, helmets, smoke detectors, revolving lights, etc.

Precision Parts – Camera parts, watch parts

Office Automation Equipment – Lap-top personal computer housings, PDA housings, CD-ROM drive parts, laser printer chassis, OA equipment housings, digital camera housings

Household Applications – Electrical outlets, irons, microwave ranges, coffee makers, electric shavers, hairdryers, decorative light fixtures

Optical – Optical lenses and optical discs such as CD, CD-ROM, CD-R, MO, MD, DVD

Communications – Mobile phone housings and pager parts