PLA filament

(Polylactic acid)

Basic Info

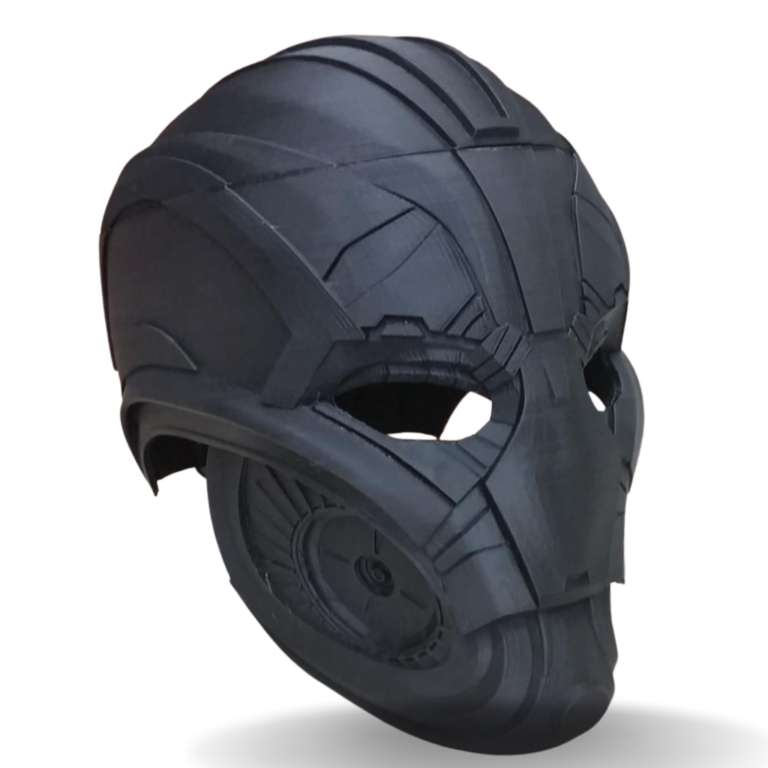

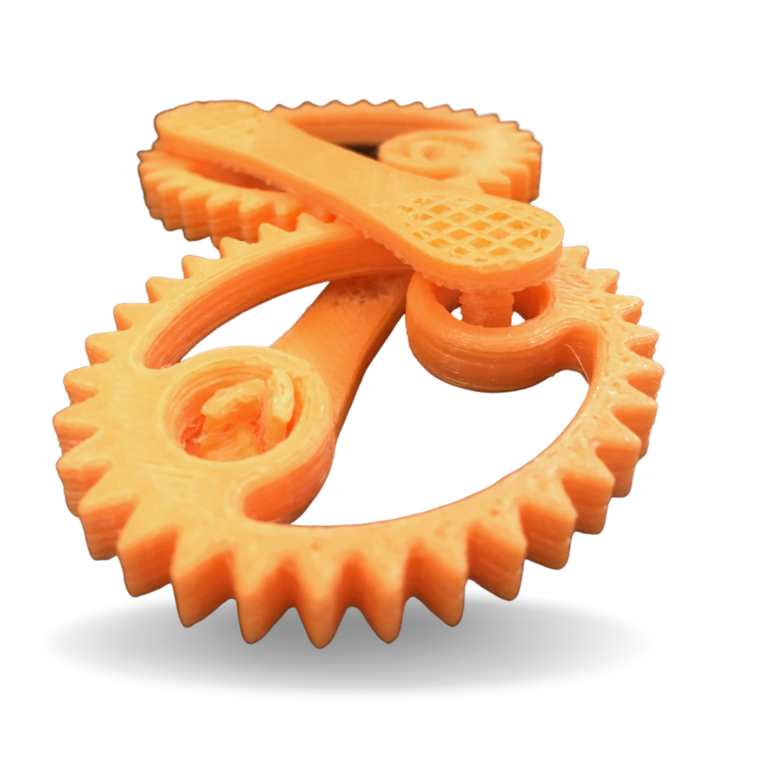

PLA Filament is one of the easiest materials to print. It is inexpensive and suitable (not only) for beginners. It’s usually used for printing detailed models, figures, and quick prototypes that don’t require high mechanical, chemical, or temperature resistance

Description

PLA FIlament (Polylactic acid), also known as PLA, is a thermoplastic monomer derived from renewable, organic sources such as corn starch or sugarcane. Using biomass resources makes PLA production different from most plastics, which are produced using fossil fuels through the distillation and polymerization of petroleum. Despite the raw material differences, PLA can be produced using the same equipment as petrochemical plastics, making PLA manufacturing processes relatively cost efficient. PLA is the second most produced bioplastic (after thermoplastic starch) and has similar characteristics to polypropylene (PP), polyethylene (PE), or polystyrene (PS), as well as being biodegradable.

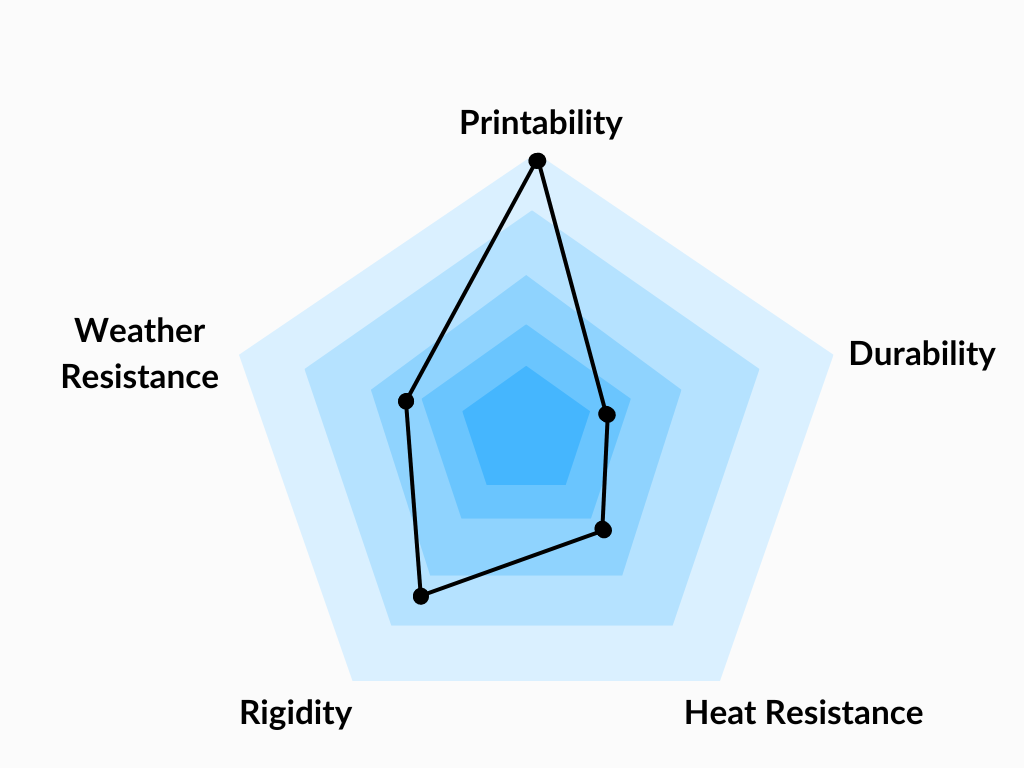

Chart

Pros and Cons of using PLA Filament

| Pros | Cons |

|---|---|

| Environmentally friendly (if disposed of correctly) | Low heat resistance |

| Easy to 3D print | Comparatively low strength |

| Safe for use in applications such as food containers and medical devices | Machine processing can be difficult |

| Comes with a wide range of composite and colour options to provide different properties and appearances |

Applications

PLA Filament has a number of common uses, including for medical and food purposes. It is also widely used as a 3D printing feedstock for desktop fused filament fabrication 3D printers. PLA Filament is popular for 3D printing as it can easily be sanded, painted or post processed. A user friendly material, this plastic works with low extrusion temperatures and there is no need for a heated bed, printer chamber or reinforced nozzle. Another benefit is that PLA behaves better than many tougher plastics and also doesn’t release fumes or bad odors. Storage is easy and it can be produced in a variety of colors and as the base for a range of composites with additional properties (see above).

Because PLA Filament can degrade into lactic acid, it can be used for medical implants such as anchors, screws, plates, pins, rods or as a mesh. It breaks down in between 6 months and 2 years, depending on the exact type of material used. This means that these products can gradually transfer a load from a PLA support structure to the body as it heals.

PLA Filament, created with injection molding, casting or by being spun, is also used as a decomposable packaging material, film or for cups and bags. It is used for compost bags, food packaging, disposable tableware, and loose fill packaging. As a fiber or nonwoven fabric, PLA is used for upholstery, disposable clothing, feminine hygiene products and nappies.

Sources :

https://www.twi-global.com/technical-knowledge/faqs/what-is-pla#:~:text=PLA%20is%20a%20type%20of,on%20PLA%20production%20methods%20below.

https://help.prusa3d.com/article/pla_2062