Flex filament

(Thermoplastic Elastomers)

Basic Info

Description

Flexible filaments are made of Thermoplastic Elastomers (TPE) which are a blend of hard plastic and rubber. As the name suggests, this material is elastic in nature allowing the plastic to be stretched and flexed easily. There are several types of TPE, with Thermoplastic polyurethane (TPU) being the most commonly used among 3D printing filaments. In many cases, these terms are used interchangeably, along with popular brand names such as Ninjaflex. The degree of elasticity in the plastic depends on the type of TPE and the chemical formulation used by the manufacturer. For example, some filaments can be partially flexible like a car tire but others can be elastic and fully flexible like a rubber band. This guide will cover tips to help you with both of these variations of flexible filaments.PVB is not suitable for printing mechanical parts. Its dimensional stability is great, tenacity and tensile strength is comparable to CPE (and low-tier PETG) but temperature resistance is similar to PLA.Since it’s an easy-to-print material (similar to PLA), PVB is a great choice for both experienced and new 3D printer users that would like to try something new.

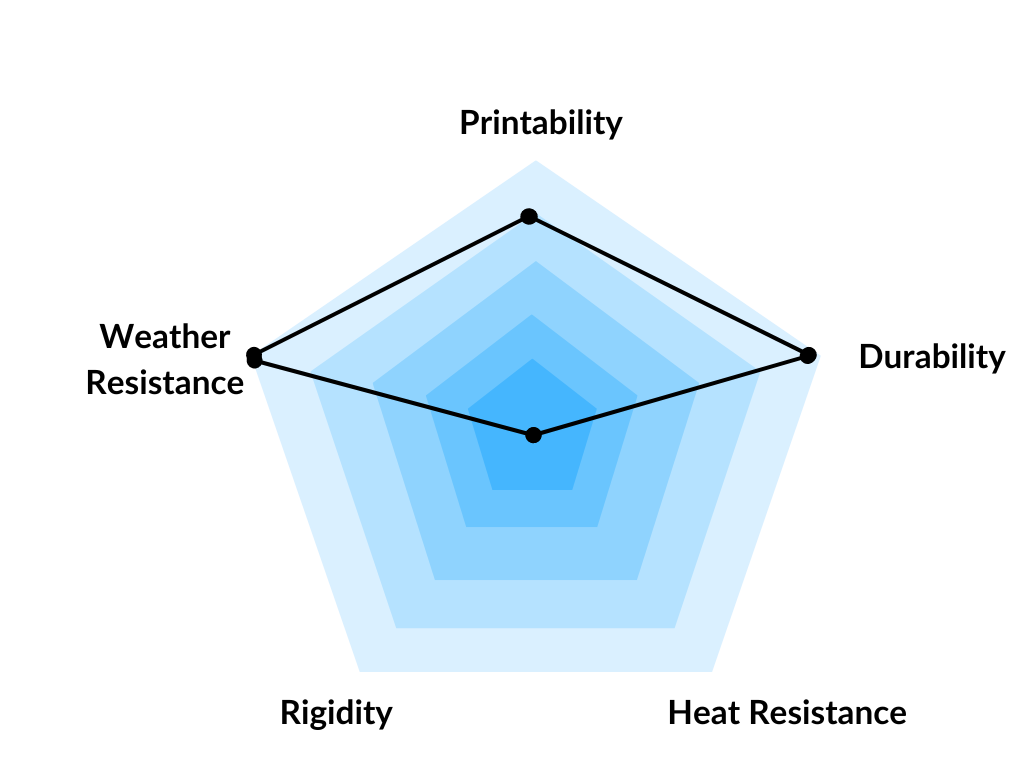

Chart

Pros and Cons of using Flexible filament

| Pros | Cons |

|---|---|

Flexible and soft | Difficult to print |

Excellent vibration dampening | Poor bridging characteristics |

Long shelf life | Possibility of blobs and stringing |

Good impact resistance | Possibility of blobs and stringing |

Applications

Functional prototyping and fit testing. Designers creating products or parts with elastic properties can test functionality with true-to-life flexibility – for example a phone case or seal

Custom tooling. Flexible filaments enable the creation of tools with ductile elements, such as handles or gripper parts

End-use parts. Rubber-like properties are ideal for many usable or spare parts. In particular, materials like TPU can offer softer contact points to avoid machinery damaging goods on production lines