PVB filament

(Polyvinyl butyral)

Basic Info

Description

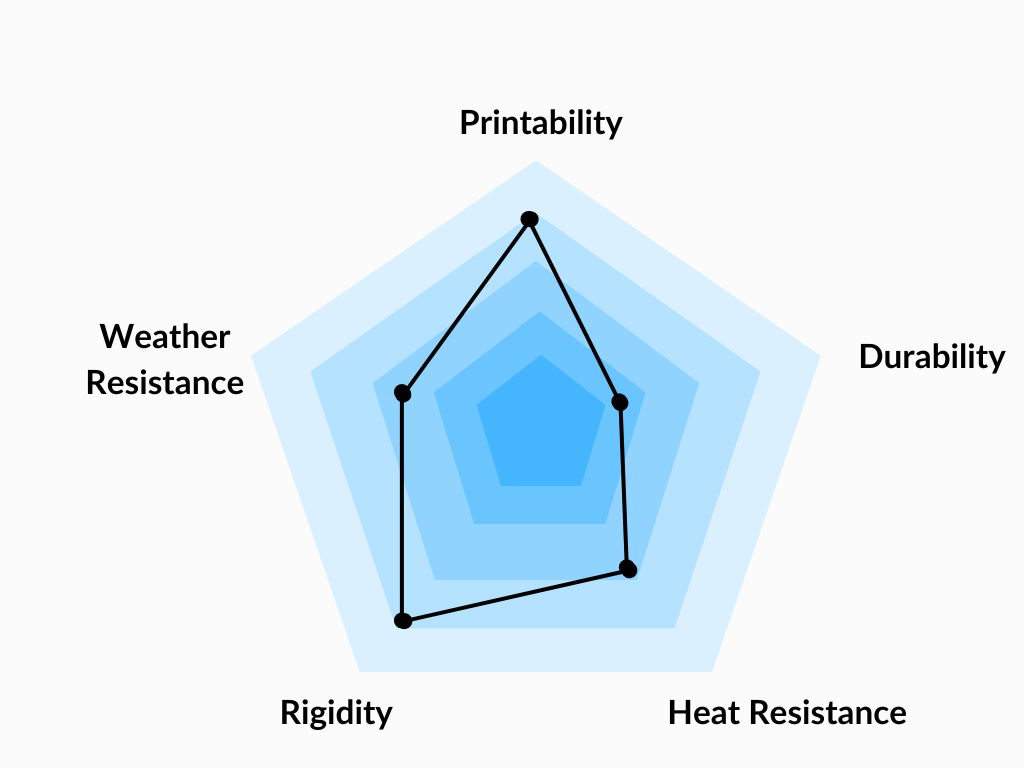

PVB Filament (Polyvinyl butyral) has similar print settings to PLA, mechanical properties are comparable with CPE or low-tier PETG. Thanks to its translucency and IPA smoothing, it is an ideal choice when you want to make design objects, such as unconventional vases, jewellery, lamp shades and similar objects. The most ideal are models that require partially transparent surface. It’s recommended to tweak print settings, especially layer height, number of perimeters and infill density. We recommend printing with large nozzle diameter and spiral vase mode.

PVB is not suitable for printing mechanical parts. Its dimensional stability is great, tenacity and tensile strength is comparable to CPE (and low-tier PETG) but temperature resistance is similar to PLA.

Since it’s an easy-to-print material (similar to PLA), PVB is a great choice for both experienced and new 3D printer users that would like to try something new.

Chart

Pros and Cons of using PVB Filament

| Pros | Cons |

|---|---|

| IPA chemical smoothing | Low layer to layer adhesion |

| Great surface adhesion | Hygroscopic filament (absorbs moisture) |

| Good tenacity (similar to CPE) | Higher price |

| Good electric insulation properties |

Applications

- The most important application of PVB film is laminated safety glass for automobile windshields. PVB films find also applications in the construction industry as laminated safety and security glass, as well as in the photovoltaic industry to improve the long-term durability of solar modules.

- PVB is suitable for flexible packaging applications. It is considered non-toxic and some grades have received food contact approval

- Polyvinyl butyral resins are also commonly used as binders in inks, paints and primers. Regardless of the application, polyvinyl butyral is able to adhere exceptionally well to virtually any materials due to its excellent bonding properties.

- Their optical clarity and excellent adhesive and film-forming properties make polyvinyl butyral resins a truly versatile ingredient in adhesion primers, anti-corrosion primers, stove enamel and glazes.